Why More Automotive Manufacturers Are Embracing Lightweight Lifting Gear: A Dual Solution for Safety and Efficiency

Why are an increasing number of automotive manufacturers opting for lightweight lifting gear? This article reveals the dual benefits of enhanced safety and improved efficiency in automotive production lines. It offers an in-depth analysis of high-strength lightweight materials and adjustable clamping mechanisms that significantly boost operational productivity while reducing accident risks. Proven across manufacturing, maintenance, and warehousing scenarios, these solutions help companies optimize costs and elevate performance.

Why Are More Automotive Manufacturers Embracing Lightweight Lifting Devices? A Dual Solution for Safety and Efficiency

The automotive industry continues to innovate—not only in vehicle design but also in how manufacturing processes are optimized for safety, speed, and cost-effectiveness. Among recent trends, the adoption of lightweight lifting devices in automotive production lines has gained significant momentum, presenting compelling solutions that reconcile enhanced operational efficiency with elevated safety standards.

Addressing Core Industry Challenges: Safety Risks and Inefficient Traditional Lifting Methods

Traditional lifting equipment used in automotive manufacturing has long been associated with multiple limitations, including:

- Heavy weight leading to increased operator fatigue and higher injury risks

- Complex handling procedures causing extended downtime during assembly or maintenance

- Limited adaptability across diverse automotive components and workflow stages

Studies indicate that traditional rigs contribute up to a 25% longer operational cycle time compared to modern lifting solutions, while workplace injury rates linked to manual lifting can escalate operational costs by more than 15% annually. These challenges underscore the urgent need for tools that enhance safety without compromising production speed.

Innovative Features of Lightweight Lifting Devices Enhancing the Automotive Production Line

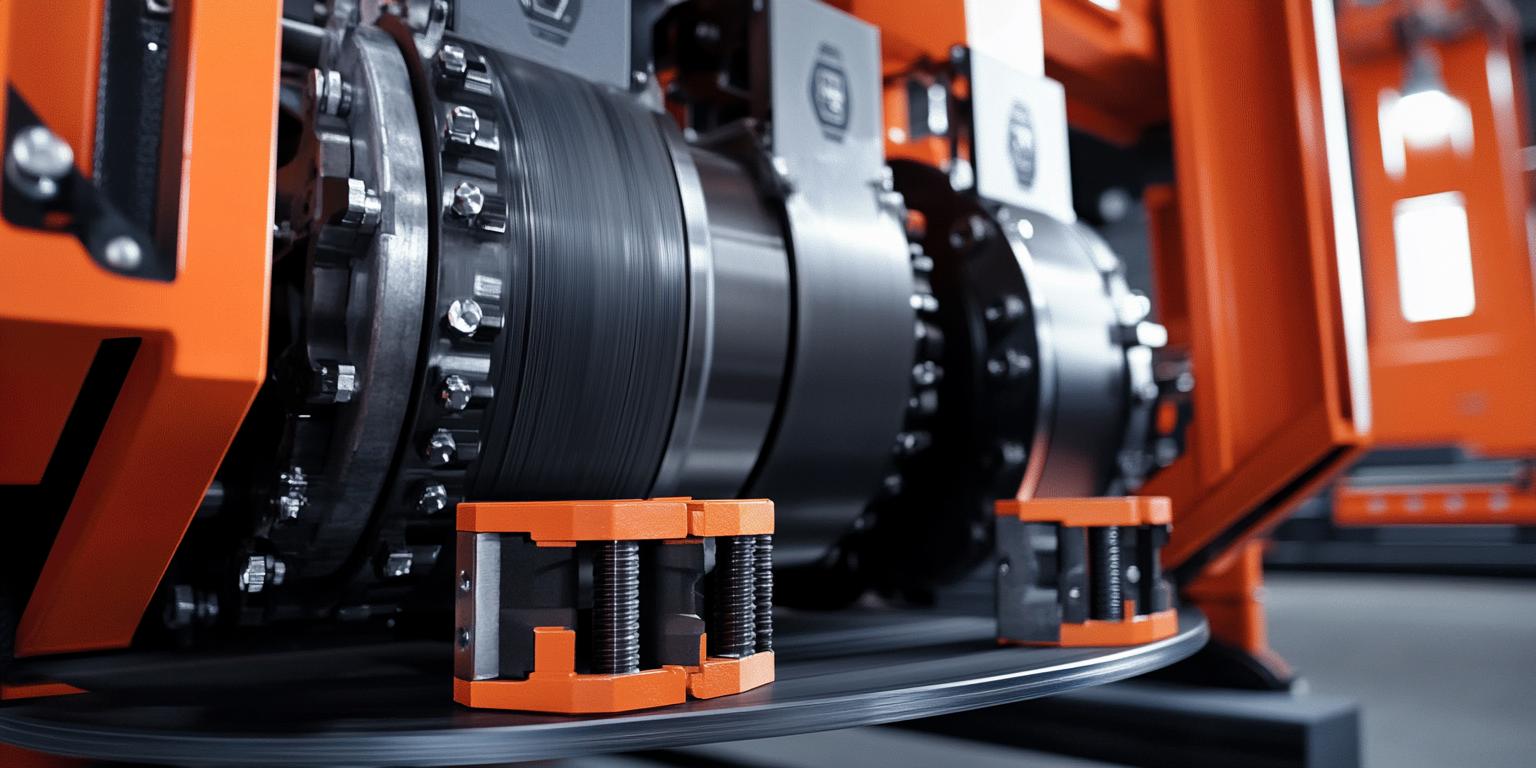

New-generation lifting devices optimize automotive workflows by integrating several key innovations:

- Advanced Lightweight Materials: Ultra-high-strength alloys and composite materials reduce device weight by up to 40%, easing manual handling and decreasing operator fatigue.

- Smart Clamping Mechanisms: Adjustable, precision-engineered clamps ensure secure grip on diverse vehicle components, minimizing slippage and accidental drops.

- Multi-Scenario Adaptability: Configurable designs cater to assembly lines, maintenance bays, and warehousing needs, enabling seamless transitions across production stages.

Table 1: Performance Comparison of Lightweight vs. Traditional Lifting Devices

| Metric |

Traditional Devices |

Lightweight Devices |

Improvement |

| Average Weight (kg) |

35 |

21 |

-40% |

| Operation Cycle Time (min) |

15 |

10.5 |

-30% |

| Safety Incident Rate (per 1000 ops) |

4.2 |

1.5 |

-64% |

| Operator Fatigue (subjective score) |

7/10 |

4/10 |

-43% |

Real-World Efficiency Gains and Safety Improvements

Implementation data from leading automotive manufacturers reveal transformative impacts:

- Operational Efficiency: Assembly lines report up to 30% reduction in lifting-related cycle times, contributing to overall production acceleration without compromising precision.

- Safety Enhancements: The improved ergonomics and secure clamping reduced workplace accidents by over 60%, mitigating downtime and legal liabilities.

- Worker Welfare: Operators experience markedly less physical strain, fostering higher morale and lower absenteeism rates.

Expanding Applications: From Full Vehicle Assembly to Heavy Component Maintenance

The adaptability of lightweight lifting devices shines through their versatility across the automotive value chain:

- Complete Vehicle Assembly: Enables precise, efficient handling of chassis and body panels, facilitating faster line throughput.

- Component Repair & Maintenance: Assists in safely repairing engines, transmissions, and suspension parts, reducing manual handling risks.

- Heavy Equipment Warehousing: Streamlines loading and offloading of bulky automotive equipment, ensuring storage efficiency and operator safety.

These devices not only complement existing workflows but also act as catalysts for greater process integration and automation readiness.

Case Insights: Empowering Automotive Producers to Cut Costs and Enhance Production Quality

One notable automotive supplier implemented lightweight lifting tools line-wide and observed:

- 35% decrease in equipment-related downtime over 12 months

- Reduction of workplace injury claims by 58%

- Positive feedback from 90% of operators citing improved ease of use and comfort

These outcomes emphasize the tools’ role beyond mere equipment — as essential contributors to optimized manufacturing ecosystems.

Discover How Lightweight Lifting Devices Can Elevate Your Factory Safety and Efficiency Today