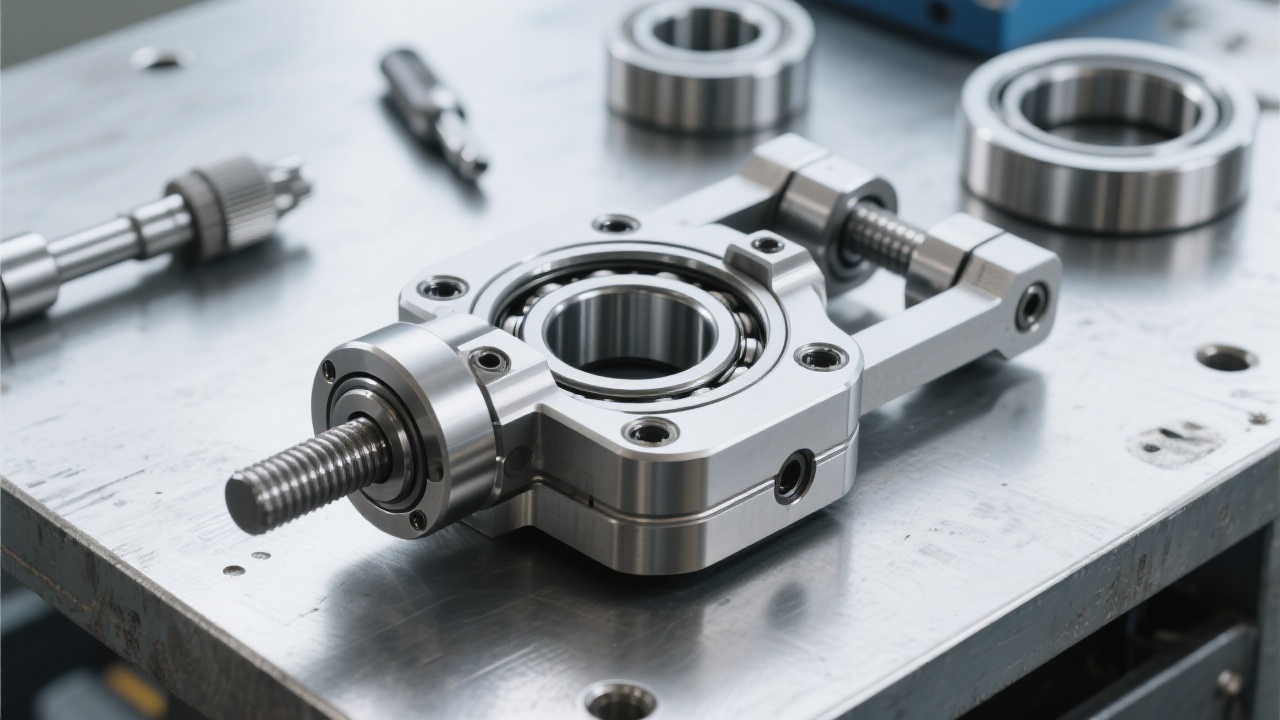

In industries such as bearing manufacturing, forging, and power generation, operational safety and efficiency in handling ring-shaped components remain critical challenges. The demanding environments require specialized tools that not only secure heavy loads but also minimize downtime caused by component damage or handling errors. Enter the Heavy-Duty Bearing Ring Lifting Tool: engineered from high-strength alloy steel and featuring a unique clamping mechanism combined with a compact design, this tool addresses the persistent risks of slippage and deformation, ensuring consistent and reliable handling throughout production workflows.

Conventional methods of lifting and moving bearing rings often expose operators and equipment to several risks:

• Slippage during transfer causing damage or injury

• Deformation of fragile components reducing quality

• Time-consuming adjustments leading to operational bottlenecks

• Insufficient load capacity posing safety hazards

The heavy-duty bearing ring lifting tool enhances load capacity by up to 40% compared to traditional clamps, thanks to a meticulously engineered high-strength alloy steel construction. Its innovative clamp stability system eliminates slippage, securing rings firmly yet gently to prevent deformation. The tool’s lightweight and compact design improves operator maneuverability—cutting handling times by approximately 25%, which directly boosts overall production efficiency.

| Feature | Benefit | Impact |

|---|---|---|

| High-Strength Alloy Steel | Exceptional durability and load-bearing capacity | Withstands heavy loads up to 2000 kg, reducing tool replacement frequency by 35% |

| Unique Clamp Mechanism | Stable and secure grip with minimal movement | Eliminates ring slippage, enhancing workplace safety by 50% |

| Compact and Portable Design | Easy maneuverability in confined spaces | Improves handling speed, saving up to 15 minutes per lift in busy production lines |

| Wear-Resistant Coating | Long-lasting performance under harsh conditions | Extends service life by up to 40%, lowering maintenance costs |

Bearing Factories: Accelerated ring lifting processes reduce cycle time by 20%, enabling higher throughput without compromising safety.

Forging Plants: Enhanced grip stability prevents component drops during high-temperature handling, crucial for operator safety.

Nuclear Power Projects: The tool meets stringent industry standards, supporting operations that demand zero tolerance for failure.

Construction Machinery: Flexible handling in tight spaces enhances equipment assembly speed and reduces labor fatigue.

Automotive Production Lines: Enables smooth, repeatable ring transfers, increasing line efficiency by up to 15%.

The lifting tool complies with ISO 12100 for machinery safety and meets ANSI B30.20 standards for below-the-hook lifting devices. This compliance assures users of documented safety, reliability, and ease of maintenance. Whether for small-scale workshops or large-scale power plants, its adaptability minimizes integration complexity, empowering decision makers with confidence.

Are you facing challenges with bearing ring handling efficiency and safety? Discover how “Heavy-Duty Bearing Ring Lifting Tools” can make every lift rock solid and every process smoother.

Make Every Lift Rock Solid – Explore Our Heavy-Duty Lifting Solutions Now