In the dynamic landscape of the automotive industry, efficiency and safety are two critical factors that manufacturers and maintenance providers constantly strive to optimize. The automotive production line lifting device emerges as a game - changer, addressing these challenges head - on. This article delves into the design features, core advantages, practical benefits, and application scenarios of this remarkable product.

The automotive industry is no stranger to efficiency bottlenecks and safety challenges. Traditional lifting methods often struggle to handle the diverse range of automotive components, leading to production delays and potential safety hazards. For example, in some large - scale automotive manufacturing plants, it was found that up to 30% of production disruptions were due to inefficient lifting equipment, and about 20% of workplace accidents were related to improper lifting operations.

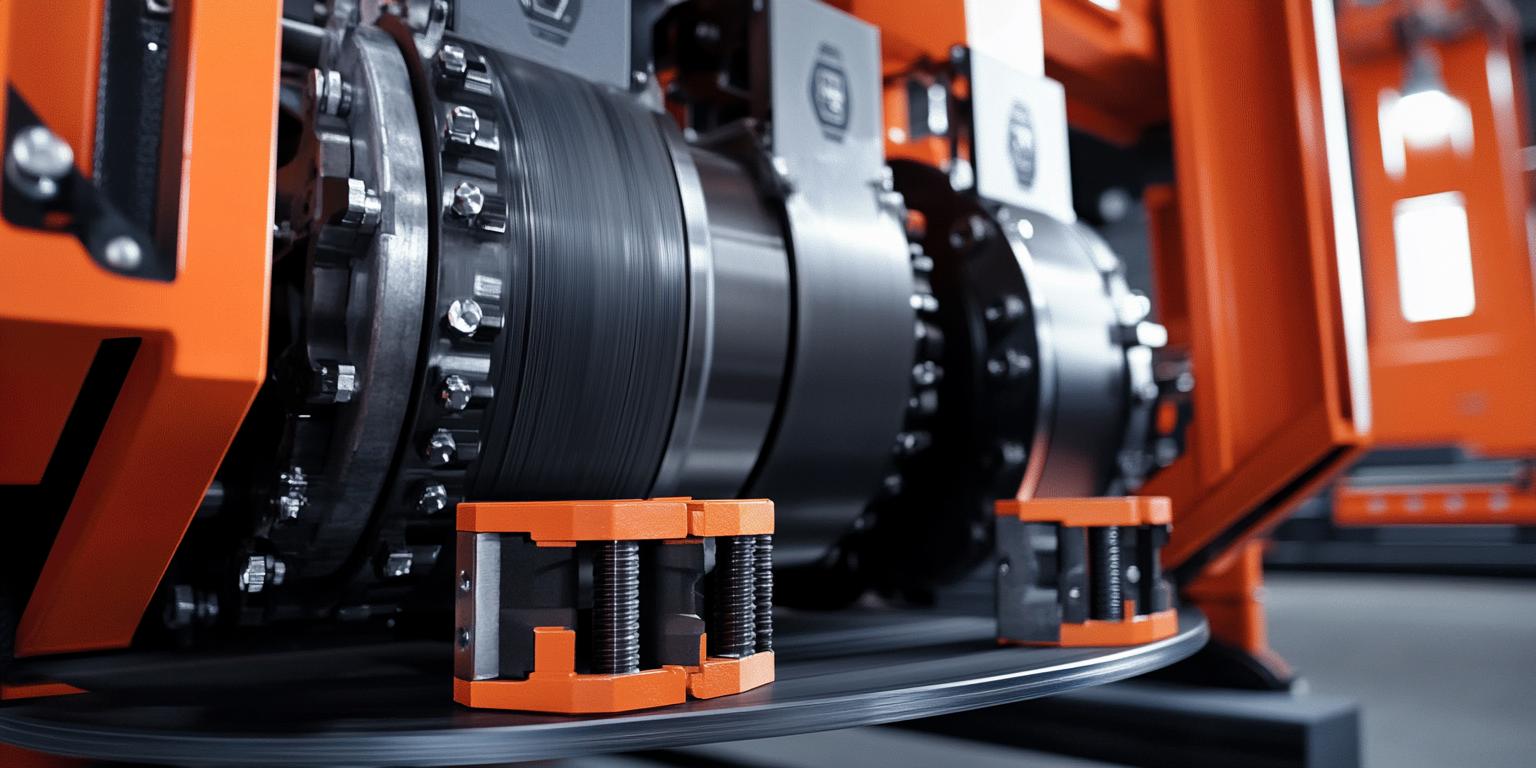

To overcome these challenges, automotive production line lifting devices are designed with several innovative features. Firstly, they are made of high - strength and lightweight materials. These materials not only reduce the overall weight of the lifting device but also ensure its durability. For instance, the use of advanced carbon fiber composites can reduce the weight of the lifting device by up to 40% compared to traditional steel - based devices, while maintaining a high load - bearing capacity.

Secondly, they are equipped with a unique clamping mechanism. This mechanism can securely hold various automotive components, regardless of their shape and size. The clamping force can be precisely adjusted, ensuring that the components are lifted safely and without damage. Additionally, the lifting devices are highly adjustable, allowing them to adapt to different production line heights and angles.

By using automotive production line lifting devices, manufacturers can significantly improve production stability. The precise lifting and placement of components reduce the risk of misalignment and damage, leading to a smoother production process. In a well - known automotive manufacturing company, after implementing these lifting devices, the production efficiency increased by 25%, and the defect rate decreased by 15%.

Worker safety is of utmost importance in the automotive industry. These lifting devices play a crucial role in ensuring operational safety. The secure clamping mechanism and high - strength materials prevent components from falling during the lifting process. According to a survey, in workplaces where these lifting devices are used, the number of lifting - related accidents has decreased by up to 40%.

The use of these lifting devices also helps to reduce labor intensity. Workers no longer need to manually lift heavy components, which reduces physical fatigue and the risk of musculoskeletal disorders. In some cases, the labor intensity of workers has been reduced by up to 50%.

The automotive production line lifting device has a wide range of application scenarios. In the automotive manufacturing process, it can be used to lift engine blocks, transmission systems, and body panels. In the automotive repair industry, it can assist in the removal and installation of components. Moreover, it is also useful in automotive warehouses for storing and retrieving heavy parts, as well as in the maintenance of heavy machinery.

Many customers have recognized the value of automotive production line lifting devices. One customer from a large automotive manufacturing company said, "Since we started using these lifting devices, our production efficiency has improved significantly, and the safety of our workers has been better protected. It's a win - win situation."

If you are looking for a reliable solution to improve production efficiency and safety in your automotive - related business, the automotive production line lifting device is the answer. Contact us now to learn more!