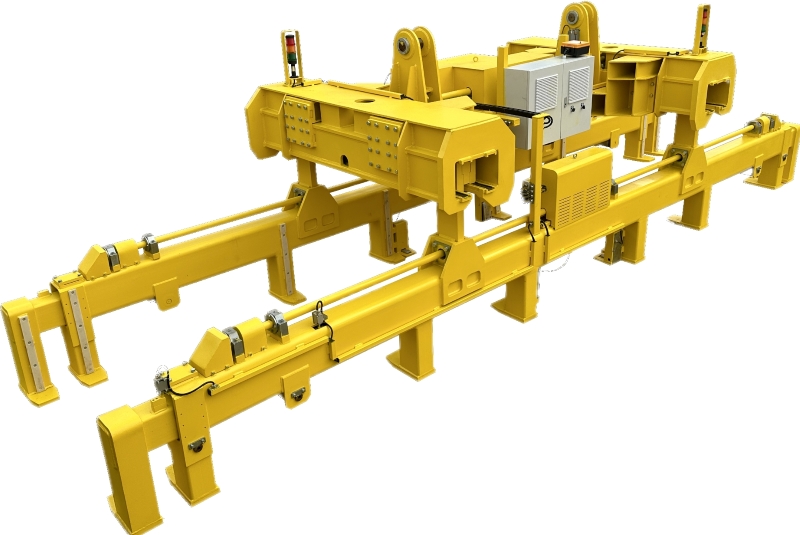

In today’s competitive manufacturing and logistics landscape, enterprises across panel production, processing centers, warehousing, ports, and construction rely increasingly on advanced material handling solutions. High-strength panel handling and stacking tools, engineered to endure loads ranging from 2 to 60 tons, combine superior materials with innovative clamping systems that redefine operational efficiency and safety standards. This article explores how these multi-driven tools—available in mechanical, electric, pneumatic, and hydraulic variants—empower enterprises to optimize workflows, minimize costs, and elevate productivity across the entire supply chain.

At the core of these tools lies high-grade steel and alloy composites, ensuring unrivaled durability and stability throughout heavy-duty operations. The patented clamp architecture accommodates various panel dimensions securely, mitigating damage and slippage risks during handling. By guaranteeing consistent load bearing from 2 up to 60 tons, these tools reliably serve diverse material types, from lightweight laminated panels to dense composite sheets.

Panel manufacturers experience up to 30% reduction in loading/unloading cycle times thanks to synchronized clamp-and-lift mechanisms. This efficiency gain accelerates throughput, reducing bottlenecks in high-volume production lines. Real-world case studies report an increase in output by over 25% after implementing these stackers into production logistics, highlighting their pivotal role in aligning manufacturing speed with shipping schedules.

Processing centers benefit notably from the tools’ ergonomic design and precise clamping control, drastically reducing manual handling risks. Automated or semi-automated drives—electric or pneumatic—facilitate smooth, continuous material flow. Statistical data reveals a 40% decrease in workplace injuries related to panel handling when these tools are integrated, underscoring their invaluable contribution to occupational safety.

Warehouses handling bulky panels face space constraints and logistical complexities. These tools enable compact, secure stacking, reducing spatial footprint by up to 35%. Enhanced maneuverability and multi-axis positioning capabilities facilitate faster stacking and retrieval, improving average inventory turnover rates by approximately 20%. Integration with warehouse management systems (WMS) further streamlines operations.

Ports and shipping terminals demand rapid turnaround of heavy loads. Multi-driven panel handling equipment ensures stable, high-speed lifts and transfers, reducing average container loading time by up to 25%. The tools’ modular drive options adapt to available power sources and environmental conditions, guaranteeing operational continuity despite variable factors such as weather or dock layout. Customers report a 15% improvement in overall logistics throughput after adoption.

Construction sites present uneven terrain and unpredictable conditions. The panel stacking tools’ rugged frames and advanced safety interlocks ensure secure material handling on-site, mitigating downtime caused by mishandling or accidents. Hydraulic-powered models offer precise lifting control even under fluctuating power availability. Site managers have observed a 30% reduction in material damage and related delays due to enhanced transport reliability.

Offering mechanical, electric, pneumatic, and hydraulic drives, these tools seamlessly integrate into diverse operational ecosystems. This flexibility grants businesses the freedom to select power modes based on infrastructure, cost-efficiency goals, and environmental regulations. The adaptability bolsters return on investment by extending usability across multiple shifts and locations without extensive retrofitting.

| Application Sector | Efficiency Improvement | Safety Impact | Space Optimization |

|---|---|---|---|

| Panel Production | +30% throughput | +25% injury prevention | N/A |

| Processing Centers | +20% handling speed | -40% accidents | N/A |

| Warehousing | +20% turnover | Improved ergonomics | -35% footprint |

| Port Operations | +15% turnaround | Enhanced load stability | N/A |

| Construction | +10% worksite speed | -30% material damage | N/A |

The compelling benefits demonstrated by real-world implementations around the globe prove that high-strength panel handling and stacking tools not only promise but deliver substantial gains. These solutions redefine material handling from a logistical challenge into a strategic asset that underpins cost leadership and operational excellence.

Discover How This Tool Can Revolutionize Your Material Handling Today