In the automotive industry, efficiency, safety, and cost - effectiveness are of paramount importance. One indispensable tool that meets these requirements is the multi - functional adjustable lifting device, a must - have for auto repair shops. This article will delve into the technical features, core advantages, and practical benefits of this remarkable device.

The adjustable lifting device is crafted from high - strength, lightweight materials. For example, using advanced aluminum alloys can reduce the weight of the device by up to 30% compared to traditional steel counterparts, while still maintaining a high load - bearing capacity. This not only makes it easier to handle but also reduces the overall energy consumption during operation.

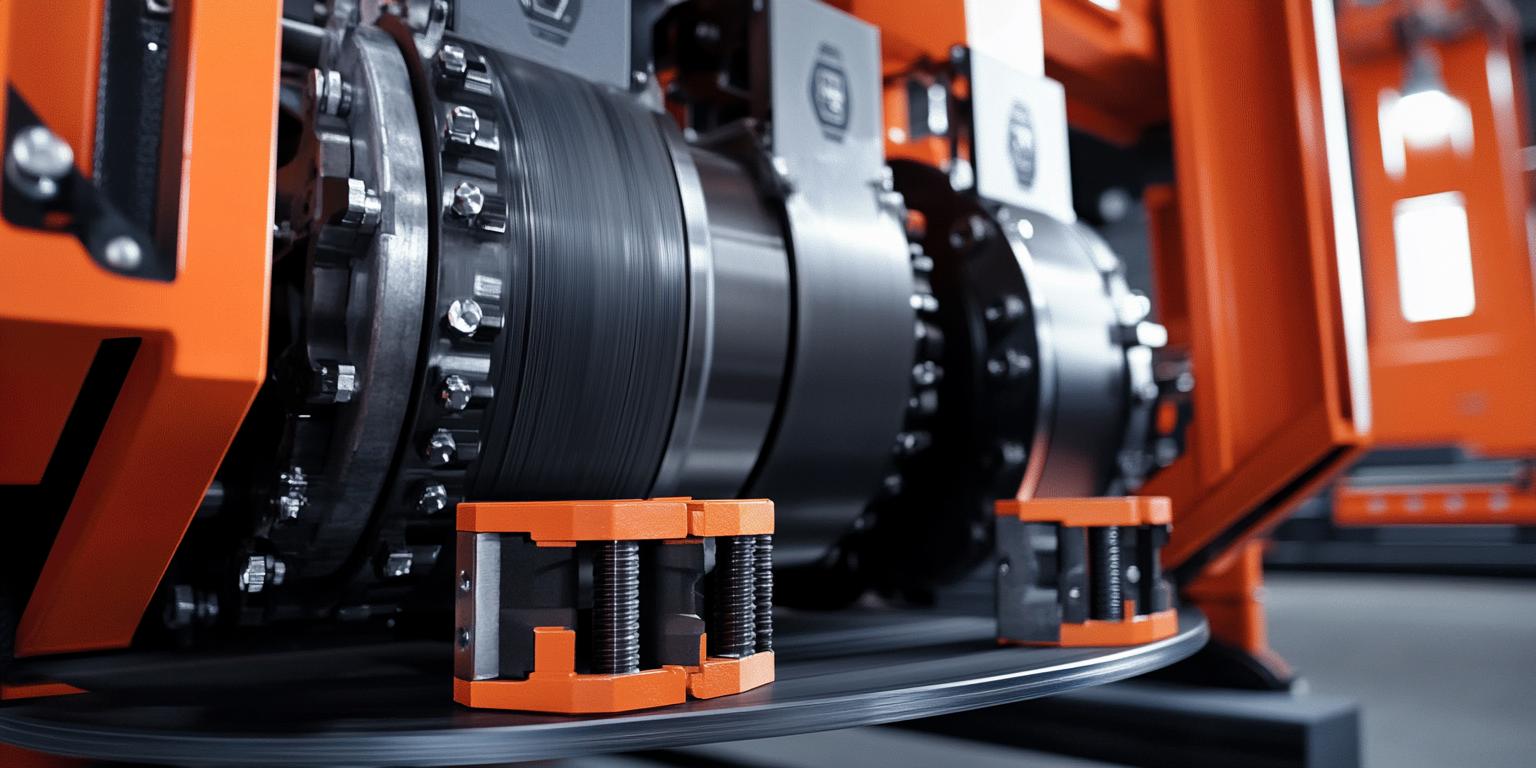

Its unique clamping mechanism is another standout feature. The clamping force can be precisely adjusted according to the size and shape of the object being lifted. Tests have shown that it can securely hold objects with a surface roughness ranging from 0.8μm to 12.5μm, ensuring a firm grip in various conditions. Moreover, the adjustable function allows the lifting height, angle, and span to be customized, providing flexibility in different work scenarios.

By reducing the time required for lifting and positioning operations, the adjustable lifting device significantly boosts productivity. In an automotive manufacturing plant, it can increase the assembly line efficiency by approximately 25%. Workers no longer need to spend excessive time aligning and securing heavy components, as the device can quickly and accurately complete these tasks.

Safety is a top priority in any industrial environment. The high - strength materials and reliable clamping mechanism of this lifting device minimize the risk of accidents. According to statistics from some auto repair shops, the use of this device has reduced the incidence of lifting - related accidents by up to 40%. It also provides a stable lifting process, protecting both the operators and the lifted objects.

The lightweight design and adjustable features mean that workers do not have to exert excessive physical effort. In a typical 8 - hour workday, the use of this device can reduce the physical fatigue of workers by about 35%. This is especially beneficial in long - term operations, as it helps to maintain the health and productivity of the workforce.

The adjustable lifting device has a wide range of applications in the automotive industry:

To further illustrate the effectiveness of the adjustable lifting device, let's look at some real - world examples. A well - known automotive repair chain reported that after using this device, their average repair time per vehicle decreased from 5 hours to 3.75 hours, a reduction of 25%. Another automotive manufacturing company found that the defect rate in the assembly process dropped from 2% to 1.5% after implementing the device, thanks to its precise lifting and positioning capabilities.

"Since we started using the adjustable lifting device, our work has become much easier and safer. The adjustable features allow us to handle different types of jobs with ease, and the high - strength materials give us peace of mind." - John, an auto repair technician

Overall, the multi - functional adjustable lifting device is a game - changer in the automotive industry. Its combination of advanced technology, practical advantages, and wide - ranging applications makes it an essential tool for businesses looking to enhance efficiency and safety.

Don't miss out on this opportunity to revolutionize your automotive operations. 立即联系我们了解更多 about how this adjustable lifting device can benefit your business.