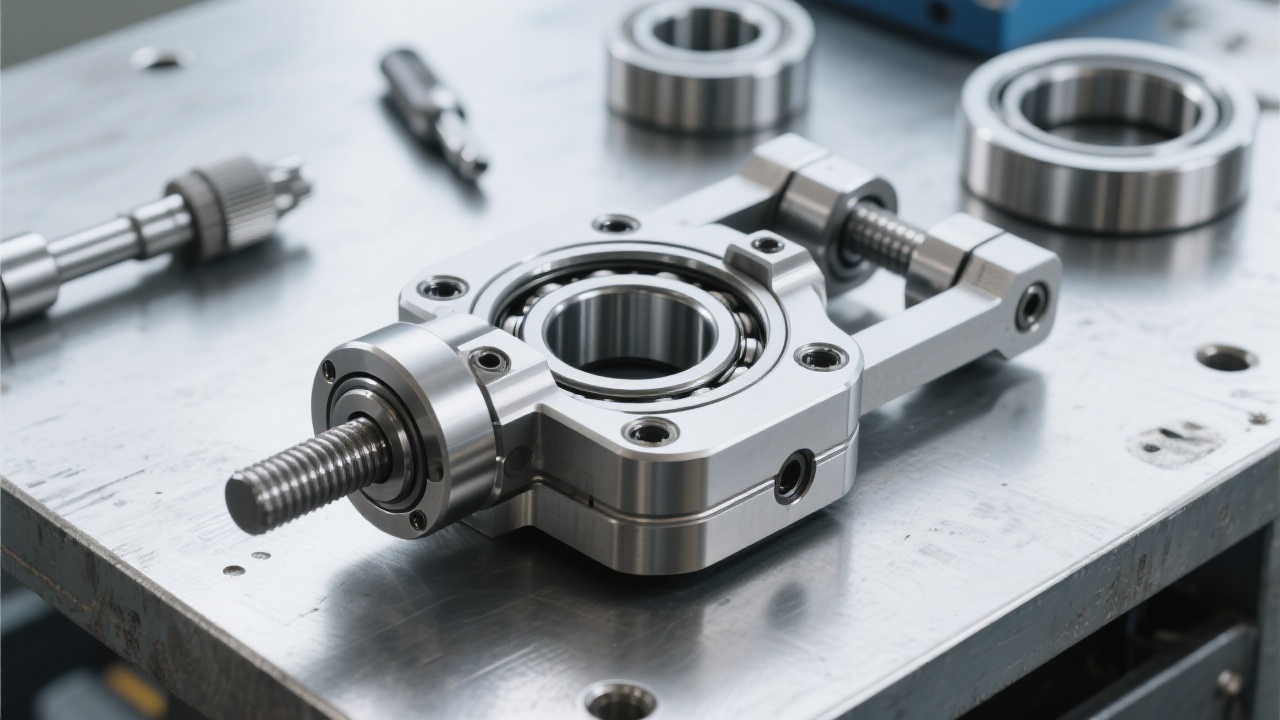

In the demanding environment of the forging industry, maintaining the integrity and safety of ring-shaped components during handling is critical to operational efficiency and worker safety. Heavy-duty bearing ring lifting tools, engineered from high-strength alloy steel and featuring innovative clamping mechanisms, are revolutionizing the way forging plants approach the lifting and transport of these vital components.

The core of these premium lifting tools lies in their robust construction. Utilizing aerospace-grade alloy steel with tensile strengths exceeding 1200 MPa, the lifting equipment withstands extreme stresses typical in forging environments. The material choice significantly reduces deformation risks, ensuring long-lasting durability.

Complementing the material strength is the patented self-tightening clamp system. Unlike traditional lifting tools that rely on manual locking methods prone to slippage, this mechanism automatically increases grip as load tension rises, dramatically minimizing the chance of accidental disengagement during lifts.

Furthermore, the compact design reduces tool weight by up to 25% compared to older models without sacrificing load capacity—typically rated up to 5 tons per tool—streamlining handling and reducing operator fatigue.

A prominent forging facility in Germany integrated these heavy-duty bearing ring lifting tools into their workflow to address recurrent safety incidents linked to slippage during ring component lifts. The customer reported a 40% decrease in near-miss events within the first six months post-implementation.

Detailed operational metrics indicated an average 15% reduction in cycle time during ring handling phases, attributed to quicker set-up and enhanced operator confidence in tool reliability. The installation also aligned with EN 13155 safety standards, reinforcing compliance adherence.

By reducing the risks associated with manual handling and slippage-caused damage, these tools contribute to prolonged component lifespan and lowered scrap rates. Manufacturers have seen a measurable 10-12% cut in reprocessing costs involving ring-shaped forgings when integrating these tools.

The secure grip also facilitates safer vertical and horizontal lifts, enabling tighter and more precise movements which are critical in assembly and machining stages that follow forging.

While the primary focus is on forging operations, the engineering behind these heavy-duty lifting tools finds successful application in multiple sectors including automotive parts manufacturing, railway axle assemblies, and large-scale machinery maintenance. Their adaptability to varying ring diameters and thicknesses, combined with reliable safety features, makes them a valuable asset for heavy industries demanding secure material handling.

Experience the next level of safety and efficiency for your forging ring handling — Discover our Heavy-Duty Bearing Ring Lifting Tools today.

How has your facility improved safety in ring component handling? Share your experiences or ask our experts your questions below — your input drives innovation across the forging industry.