In the dynamic landscape of overseas steel mills, the efficient management of steel coil lifting equipment stands as a cornerstone for seamless production operations. However, equipment managers often grapple with a multitude of challenges, from unexpected breakdowns to inefficient maintenance routines. This article delves deep into the intricacies of steel coil lifting equipment maintenance, offering practical insights and a comprehensive checklist to empower overseas steel mills in achieving optimal equipment performance.

Preventive maintenance is not just a buzzword; it's a strategic approach that can significantly reduce downtime and extend the lifespan of steel coil lifting equipment. According to industry statistics, steel mills that implement regular preventive maintenance programs can experience up to a 30% reduction in equipment failures and a 20% increase in overall production efficiency. By proactively addressing potential issues before they escalate, steel mills can avoid costly repairs and minimize disruptions to their production schedules.

Proper lubrication is essential for the smooth operation of steel coil lifting equipment. It reduces friction, prevents wear and tear, and dissipates heat. However, lubrication management is not a one-size-fits-all approach. Different components of the equipment require specific types of lubricants and lubrication intervals. For example, the hydraulic system may require a high-quality hydraulic oil with a specific viscosity rating, while the bearings may need a grease with excellent anti-wear properties.

A well-defined lubrication schedule is crucial. As a general rule of thumb, the hydraulic oil should be changed every 2,000 to 3,000 operating hours, while the bearings should be greased every 500 to 1,000 operating hours. Regularly checking the lubricant levels and quality can help identify potential issues early on and prevent costly breakdowns.

Regular inspection of key components is another critical aspect of preventive maintenance. Components such as the lifting chains, hooks, and hydraulic cylinders are subjected to high stress and wear during operation. Any signs of damage or wear can compromise the safety and performance of the equipment.

A comprehensive inspection checklist should include visual inspections for cracks, deformation, and wear, as well as non-destructive testing methods such as ultrasonic testing and magnetic particle inspection for critical components. For example, the lifting chains should be inspected every 100 to 200 operating hours for signs of elongation, corrosion, or damaged links. The hooks should be inspected for cracks and proper functioning of the safety latches.

The electrical system of steel coil lifting equipment is responsible for powering the various components and ensuring their proper operation. A malfunctioning electrical system can lead to equipment failures, safety hazards, and production delays. Therefore, regular self-inspection of the electrical system is essential.

The self-inspection process should include checking the electrical connections for tightness and corrosion, inspecting the wiring for damage or wear, and testing the functionality of the control switches and sensors. For example, the electrical connections should be tightened every 500 to 1,000 operating hours, and the wiring should be inspected for any signs of fraying or insulation damage. The control switches and sensors should be tested regularly to ensure they are providing accurate signals.

Despite the best preventive maintenance efforts, steel coil lifting equipment may still encounter occasional faults. Being able to quickly diagnose and respond to these faults is crucial to minimize downtime and prevent further damage. Some of the common faults include hydraulic system leaks, slow operation, and positioning errors.

Hydraulic system leaks are one of the most common faults in steel coil lifting equipment. They can be caused by a variety of factors, such as damaged seals, loose fittings, or worn-out hoses. A small leak can quickly escalate into a major problem if not addressed promptly, leading to a loss of hydraulic pressure and reduced equipment performance.

To diagnose a hydraulic system leak, look for signs of oil stains or puddles around the hydraulic components. Check the seals, fittings, and hoses for any visible damage or wear. If a leak is detected, the first step is to isolate the source of the leak by shutting off the hydraulic system. Then, replace the damaged seals, tighten the loose fittings, or replace the worn-out hoses.

Slow operation of steel coil lifting equipment can be frustrating and can significantly impact productivity. It can be caused by a variety of factors, such as low hydraulic pressure, a clogged filter, or a malfunctioning pump. To troubleshoot slow operation, start by checking the hydraulic fluid level and pressure. If the fluid level is low, add the appropriate hydraulic fluid. If the pressure is low, check the pump and the relief valve for proper functioning.

Next, check the filter for any signs of clogging. A clogged filter can restrict the flow of hydraulic fluid and cause the equipment to operate slowly. If the filter is clogged, replace it with a new one. Finally, check the pump for any signs of damage or wear. If the pump is malfunctioning, it may need to be repaired or replaced.

Positioning errors can occur when the steel coil lifting equipment fails to accurately position the steel coils. This can be caused by a variety of factors, such as a misaligned sensor, a malfunctioning control system, or a mechanical problem. To troubleshoot positioning errors, start by checking the sensors for proper alignment and functionality. If the sensors are misaligned, adjust them to the correct position. If the sensors are malfunctioning, replace them with new ones.

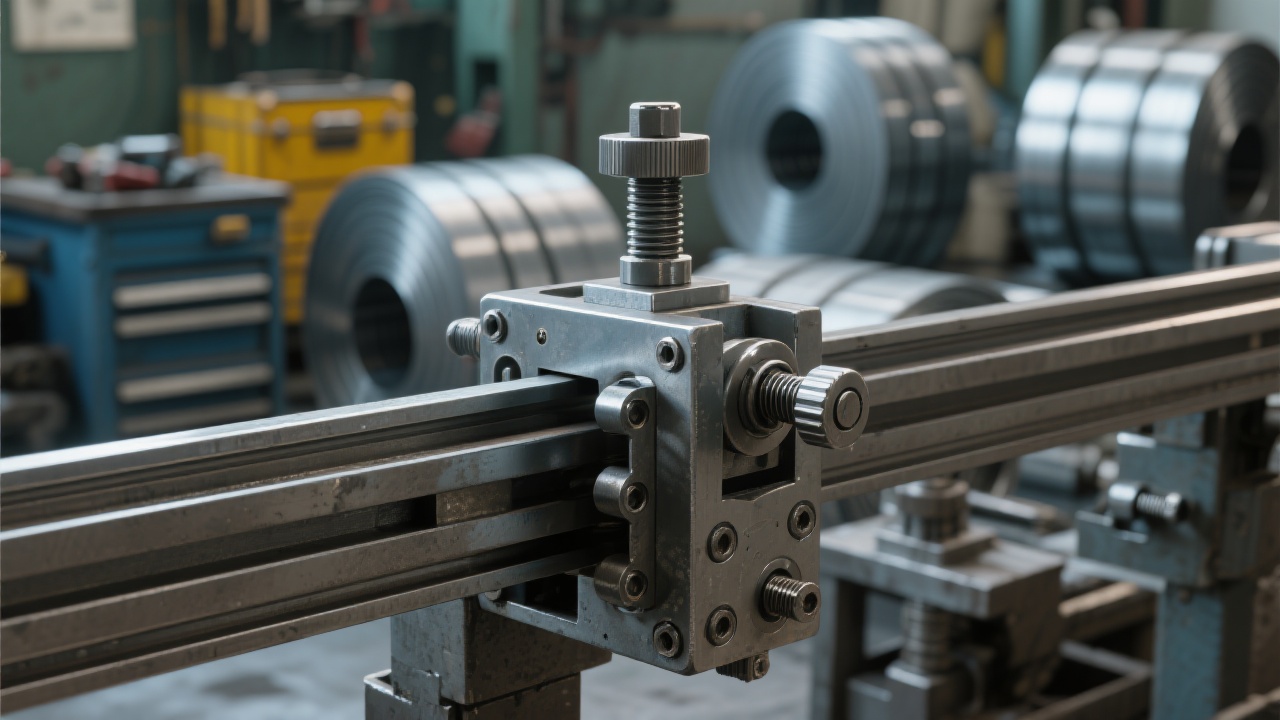

Next, check the control system for any error messages or malfunctions. If there are error messages, follow the manufacturer's instructions to troubleshoot and resolve the issues. Finally, check the mechanical components of the equipment, such as the lifting arms and the guide rails, for any signs of damage or wear. If any mechanical problems are detected, repair or replace the damaged components.

A well-structured maintenance check list is an invaluable tool for steel mill equipment managers. It provides a systematic approach to equipment maintenance, ensuring that all critical components are inspected and maintained on a regular basis. A comprehensive check list should include details such as the inspection frequency, the inspection method, and the acceptance criteria for each component.

By using a maintenance check list, steel mills can establish a standardized maintenance process, improve the accuracy and consistency of their maintenance records, and enhance the overall reliability of their equipment. Additionally, a check list can serve as a training tool for new equipment operators and maintenance personnel, ensuring that they are aware of the proper maintenance procedures and safety protocols.

In addition to implementing a preventive maintenance program and using a maintenance check list, steel mills can benefit from professional technical support and after-sales service. A reliable equipment supplier should offer comprehensive technical support, including on-site installation, training, and troubleshooting. They should also provide prompt after-sales service, including spare parts availability and repair services.

By partnering with a professional equipment supplier, steel mills can ensure that their steel coil lifting equipment is properly maintained and serviced, minimizing downtime and maximizing productivity. The supplier's technical experts can provide valuable insights and recommendations on equipment maintenance and performance optimization, helping steel mills to achieve their production goals.

Ready to revolutionize your steel coil lifting equipment maintenance? Unlock the secrets to optimal performance and efficiency with our comprehensive guide and expert support. Click here to learn more and take your steel mill operations to the next level!