Within the highly demanding steel industry, ensuring the reliability and efficiency of vertical steel coil handling equipment is crucial for uninterrupted production flow and operational safety. Preventive maintenance (PM) emerges as a strategic approach that shifts maintenance from reactive fixes to proactive care, substantially reducing downtime and extending equipment lifespan.

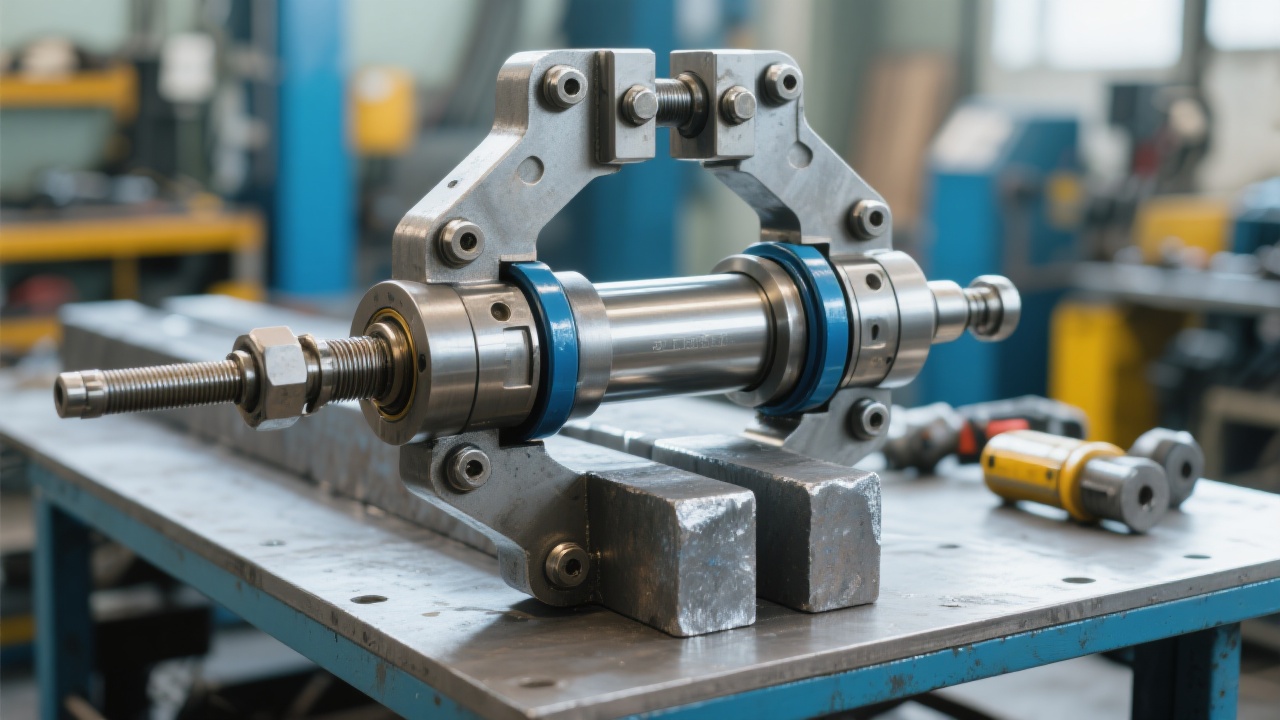

Vertical steel coil lifters incorporate critical components such as clamping mechanisms, lifting systems, and transmission drives — all exposed to rigorous mechanical stress during daily operations. According to recent industry analyses, unexpected equipment failures can contribute to up to 20% production loss annually in steel manufacturing plants.

Implementing a structured preventive maintenance process directly addresses common failure points and systematically mitigates risks, resulting in:

| Component | Daily Check | Weekly Maintenance | Monthly Inspection |

|---|---|---|---|

| Clamping Mechanism | Visual check for wear and alignment | Lubricate pivot points and check hydraulic pressure | Calibrate clamping force, test sensors |

| Lifting System (Chain & Cylinder) | Check for unusual noises and smooth operation | Grease moving parts; inspect cylinder seals | Measure chain tension and wear; replace if necessary |

| Transmission Drive | Check for leaks and overheating | Lubricate gears and bearings | Inspect belts and couplings for damage |

A systematic workflow ensures consistent execution of maintenance tasks. The process includes:

Understanding typical faults expedites maintenance response and enhances equipment uptime. Below are frequent issues with tailored diagnostics:

| Fault | Cause | Resolution |

|---|---|---|

| Insufficient Clamping Force | Hydraulic pressure drop; worn seals; sensor misalignment | Check hydraulic system pressure; replace seals; recalibrate sensors |

| Irregular Lifting Motion | Chain tension loss; lubrication deficiency; cylinder leakage | Adjust chain tension; apply grease; inspect and service cylinders |

| Transmission Drive Overheating | Gear misalignment; insufficient lubrication | Realign gears; replenish grease according to specifications |

Accurate record-keeping is the foundation of successful preventive maintenance. A standardized template captures essential details such as inspection dates, component status, fault reports, and corrective actions. This data supports trend analysis and predictive maintenance initiatives.

Download Your Free Standardized Maintenance Record Form

Transitioning from reactive to preventive maintenance empowers manufacturing plants to maximize vertical steel coil handling equipment uptime. This strategy reduces emergency repairs by up to 40%, boosts production throughput, and secures a safer working environment.

Leading enterprises that have adopted such standardized PM protocols report operational cost reductions in the range of 15-25% annually, predominantly through extended equipment life and lower spare parts consumption.

Take the first step toward a high-efficiency steel coil handling system with our expert preventive maintenance guidance and tools.