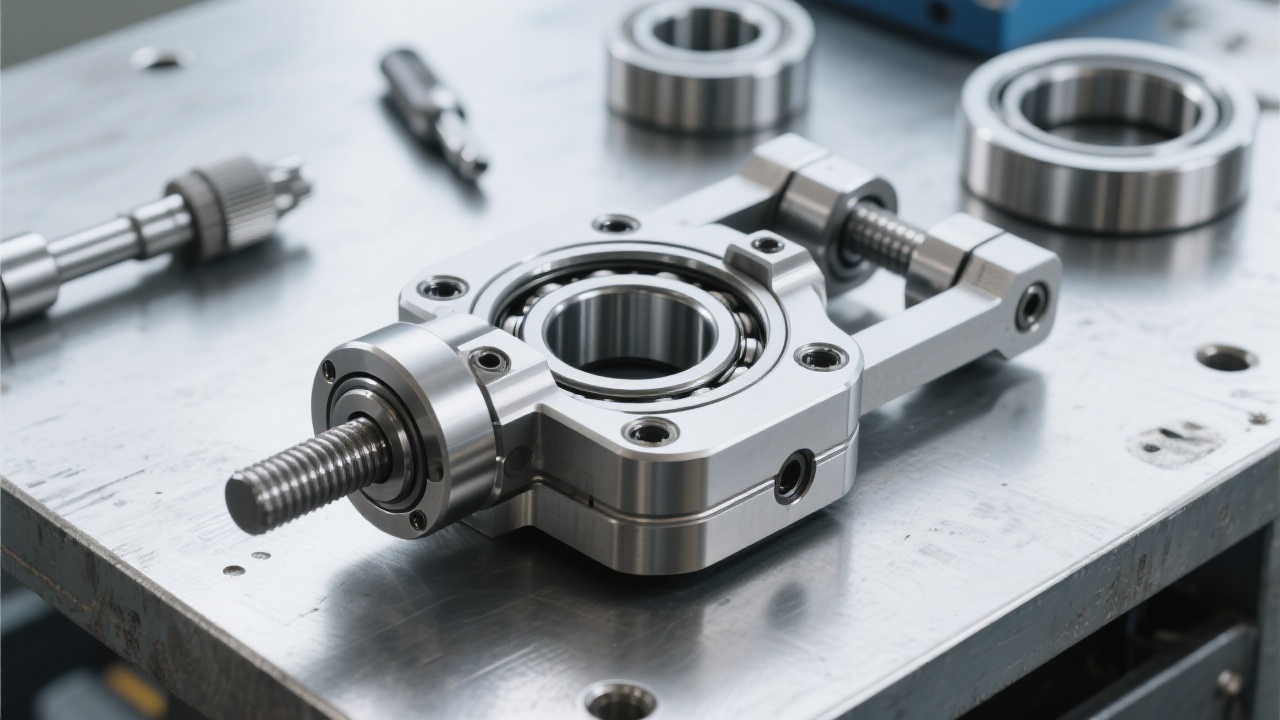

In the fields of power and mechanical engineering, the safe and efficient handling of heavy - duty bearing rings is a crucial task. The heavy - duty bearing ring lifting tool has emerged as a game - changer, offering stability and safety in critical lifting operations. This article will explore the technical advantages and industry applications of this remarkable tool.

The heavy - duty bearing ring lifting tool is made of high - strength alloy steel, which provides excellent load - bearing and wear - resistant properties. Its unique clamping mechanism, combined with a compact design, ensures that it can firmly hold the bearing ring during the lifting process. For example, in a large - scale bearing manufacturing plant, the traditional lifting methods often led to scratches on the bearing rings and had potential safety risks. However, after using this new - type lifting tool, the scratch rate was reduced by 80%, and the safety incidents related to bearing ring lifting were almost eliminated.

1. Power Industry: In the power industry, especially in nuclear power projects, the safety requirements for equipment installation and maintenance are extremely high. The heavy - duty bearing ring lifting tool can ensure the safe handling of large - diameter bearing rings in nuclear power plants. For instance, in a nuclear power project in [country], this tool was used to lift the bearing rings of steam turbines. By using this tool, the installation time of the bearing rings was shortened by 30%, which not only improved the construction efficiency but also ensured the safety of the project.

2. Mechanical Engineering: In mechanical engineering, the tool plays a vital role in the manufacturing and assembly of large - scale mechanical equipment. In a large - scale mechanical engineering project, the tool was used to lift the bearing rings of large - scale machine tools. Its compact design allowed it to work in limited spaces, and its high - strength clamping mechanism ensured the stability of the bearing rings during the lifting process. As a result, the assembly efficiency of the machine tools was increased by 25%.

3. Bearing Manufacturing: In the bearing manufacturing industry, the tool can optimize the production process. It can safely lift the forged ring components, ensuring the quality of the bearing rings during the manufacturing process. In a well - known bearing manufacturing company, after adopting this tool, the production efficiency of bearing rings was improved by 20%, and the product qualification rate was increased by 15%.

The target audience in these industries often faces problems such as low efficiency, high safety risks, and product damage during the bearing ring lifting process. The heavy - duty bearing ring lifting tool effectively solves these problems. Its high - strength material and unique clamping mechanism ensure the safety of the lifting process, and its compact design allows it to be used in various working environments.

When using the heavy - duty bearing ring lifting tool, operators should first check the integrity of the tool, including the clamping mechanism and the steel structure. Then, they need to adjust the clamping force according to the size and weight of the bearing ring. It is also important to ensure that the lifting point is in the center of the bearing ring to avoid tilting during the lifting process. For more detailed operation skills, you can refer to the operation video provided on our website.

Are you still worried about the safety and efficiency of bearing ring lifting in your projects? The heavy - duty bearing ring lifting tool is your ideal choice. It offers high reliability and wide industry applicability. Don't miss this opportunity to improve your work efficiency and ensure safety. Click here to learn more about this amazing tool!

We would love to hear your thoughts! Do you have any questions or experiences related to bearing ring lifting? Leave your comments below and let's start a discussion.